A 30-foot offshore racer designed to combine high performance, comfort and simplified handling. Developed in collaboration with Northern Light Composites, the CG30 Vento is conceived for both offshore racing and buoy regattas, with a strong focus on ORC and IRC ratings and a functional, elegant and innovative design.

Achieving the right balance between construction simplicity, comprehensive standard equipment, and technical sophistication—while keeping production costs under control—forms the foundation of the challenge undertaken by our studio for the new CG30 Vento, developed in collaboration with Northern Light Composites, a young shipyard already recognized for its hi-tech cruiser-racer production.

During the project development process, we integrated complementary technical expertise to create a yacht that is both high-performance and accessible, in terms of purchase price as well as operating costs. This collaboration enabled an in-depth preliminary analysis of the entire production process, aimed at optimizing manufacturing workflows and lamination strategies while ensuring effective cost control.

The result is a 30-foot offshore racer designed to deliver high performance both in offshore sailing and in handicap racing around the buoys, under ORC and IRC rules.

An all-round offshore racer

With an overall length just over nine meters and a beam of three meters, the CG30 Vento fits perfectly into a size range ideal for offshore racing with a reduced crew as well as for inshore racing with a full crew. Specific construction features, designed to facilitate keel and rudder removal, allow for quick and straightforward transport on a trailer.

Total displacement is 2,950 kg, including 1,350 kg of ballast, with a draft of 1.96 meters.

The extensive experience of Cossutti-Ganz Yacht Design in ORC and IRC optimization, combined with a careful analysis of stability parameters, guided the main hydrodynamic design choices. Every aspect was evaluated in terms of its impact on rating and benchmarked against the main competitors in the reference classes.

The result is a yacht that is sufficiently stiff under sail—making it suitable for offshore racing (typically double-handed)—yet not excessively stable when a significant portion of the righting moment is generated by full-crew.

Hull form development was based on an analysis of the typical weather and sea conditions encountered in the main Mediterranean and European racing areas. The CG30 Vento is therefore designed to maintain high average speeds in light and variable winds, while avoiding excessive wetted surfaces. For this reason, non-extreme hull shapes were preferred, better suited to coastal and offshore sailing rather than pure oceanic conditions.

As standard, the boat is equipped with a single transom-hung composite rudder, externally mounted. An optional twin-rudder configuration with lifting blades is available.

Design

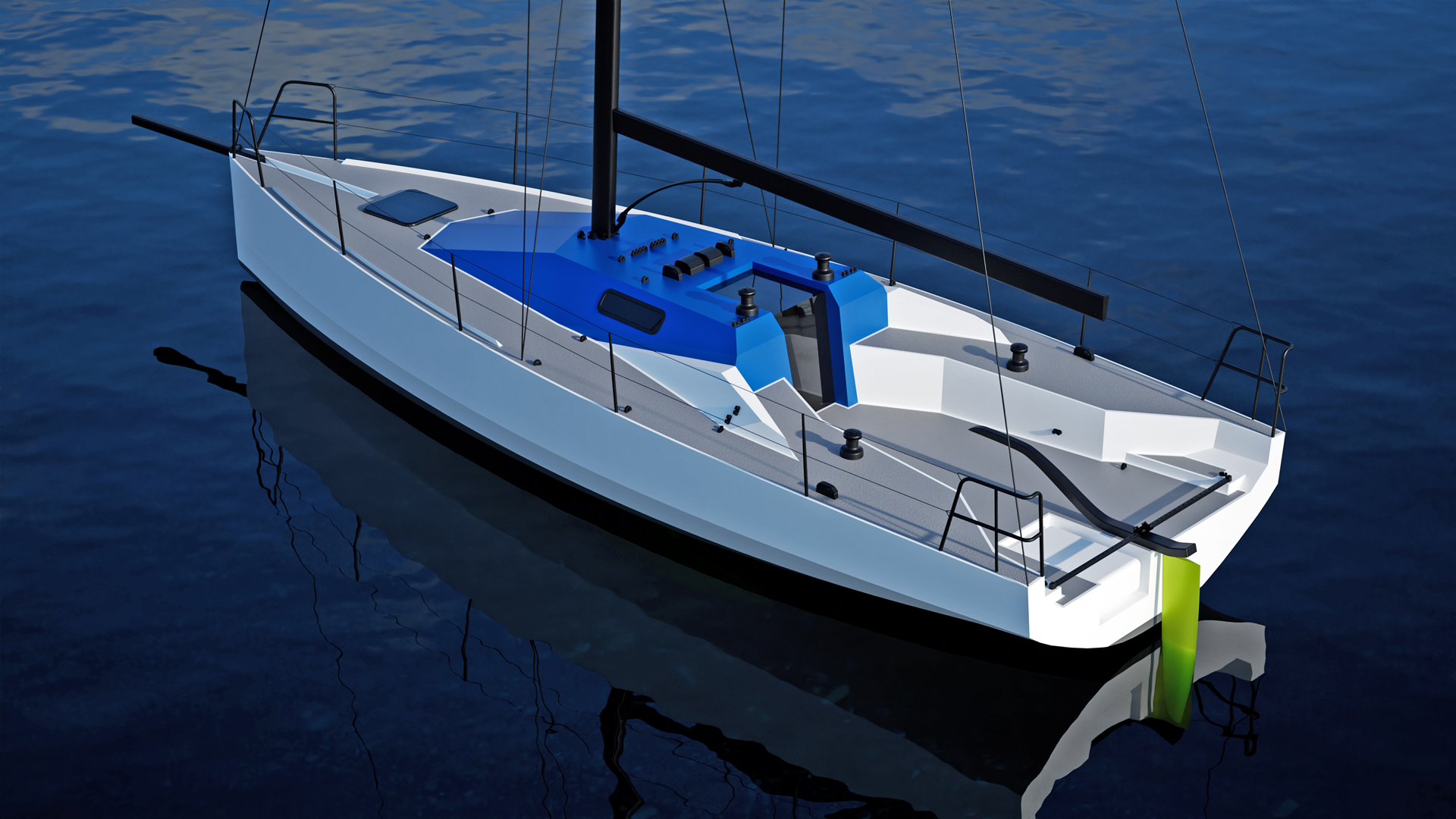

The deck design, largely realized using flat panels, recalls the aesthetics of “Stealth” aircraft and also responds to the functional requirement of reducing mold costs.

The large and comfortable cockpit is protected by two long, shaped coamings, designed to limit jets even in demanding sea conditions.

Forward, a large deck hatch provides access to the interior and can also be used as a sail stowage hatch for quick maneuvers during racing. The liferaft locker is located in the cockpit sole. Below-deck access is via a traditional sliding companionway hatch, complemented by vertical washboards.

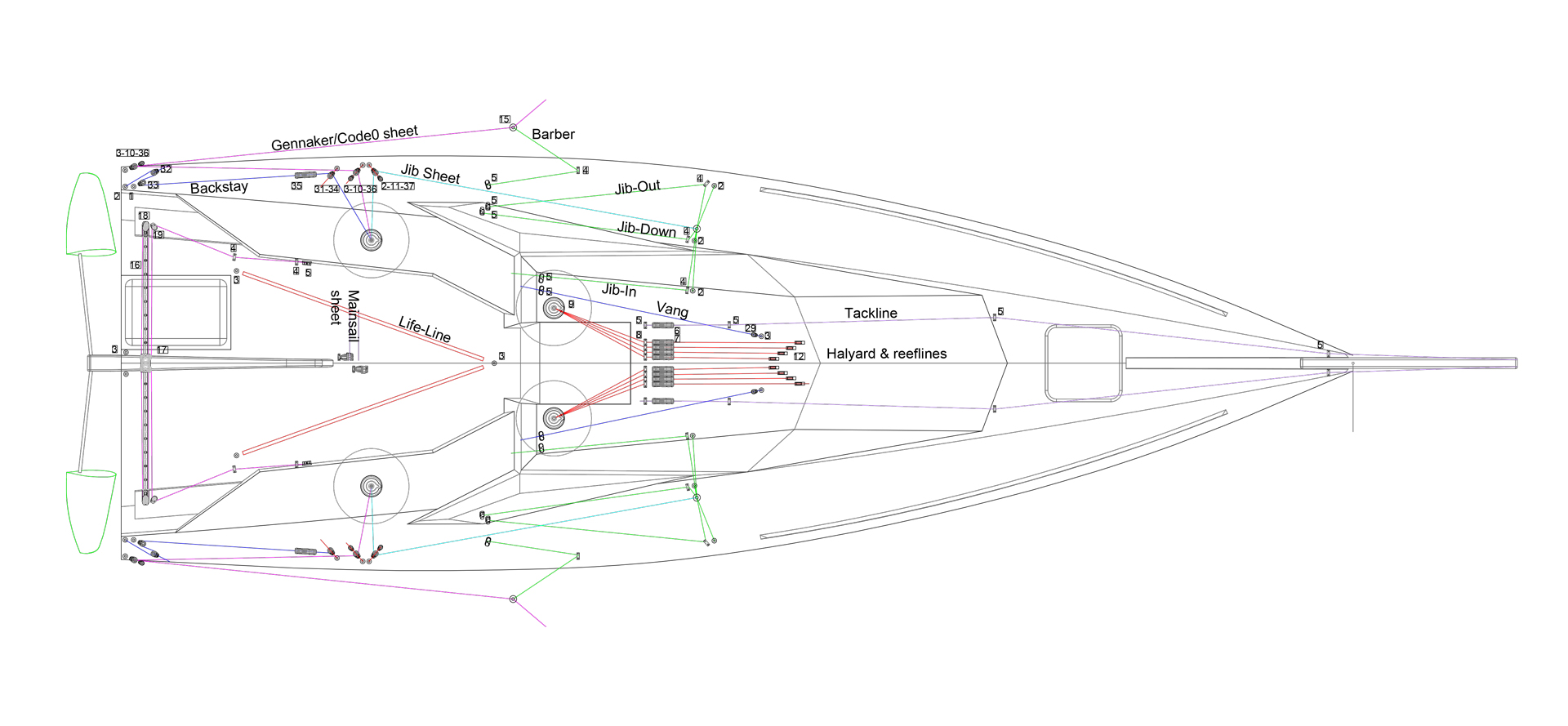

Deck layout

The rational and functional deck layout allows efficient handling when sailing solo or with a reduced crew, while still providing ample working space when the yacht is raced with a full crew.

The layout includes a carbon tiller, two Harken 35 winches in the cockpit and two additional winches on the coachroof. All control lines are led aft from the mast base and are easily reachable from the cockpit. A bank of ten rope clutches is positioned at the center of the coachroof.

The yacht is equipped with a 3D jib sheet lead system and a complete gennaker system with aft-mounted blocks.

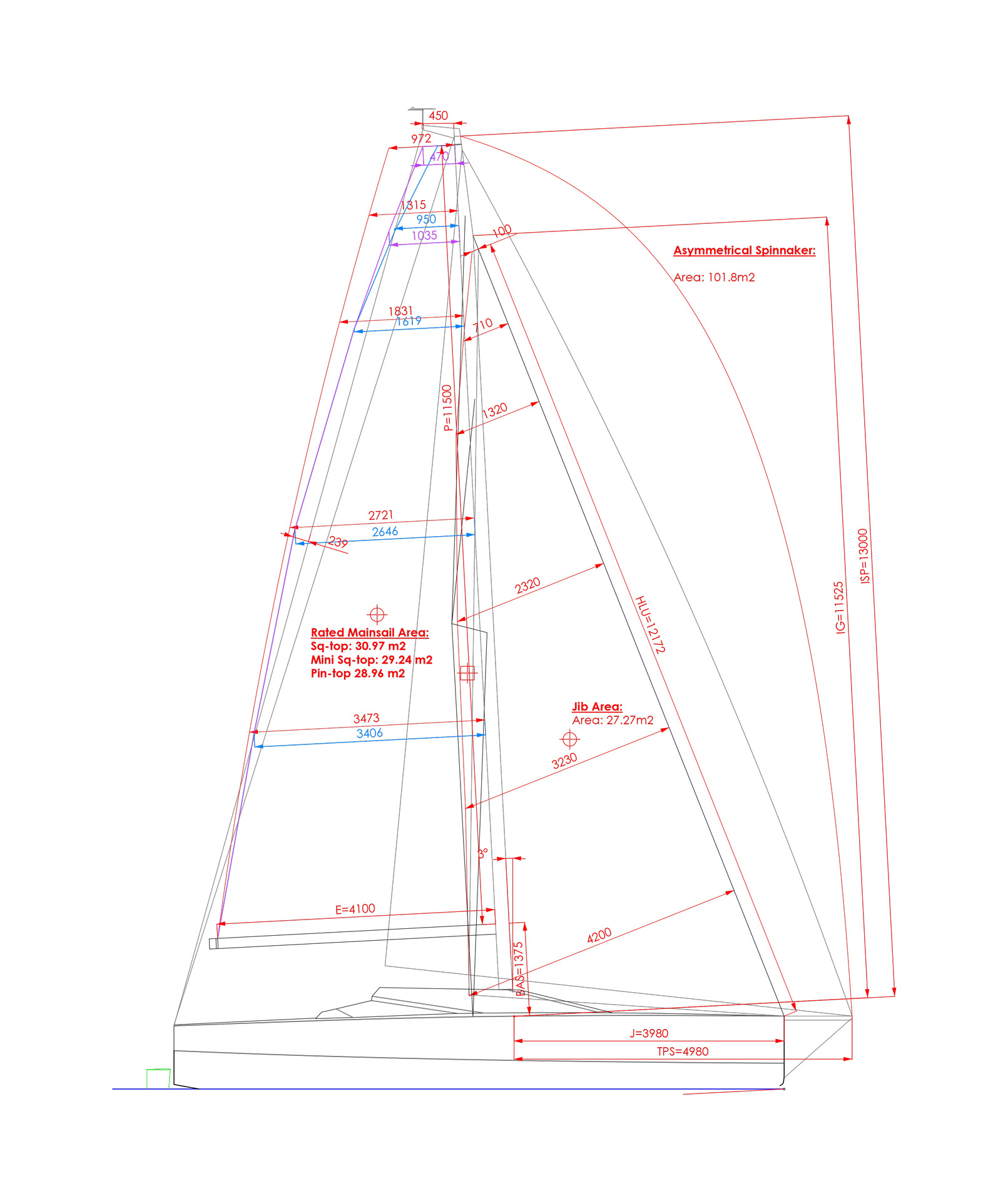

Sail plan: versatility without complexity

The sail plan features a mast position close to mid-length of the hull. Owners can choose between a square-top mainsail with double backstay or a semi square-top mainsail completed with a long masthead crane and single backstay.

The CG30 Vento features a 9/10 fractional rig with a deck-stepped mast and two swept spreaders. Upwind sail area is 56.6 m², while downwind sail area is 131 m². Mast and boom are standard in aluminum, with the option of a carbon boom or full carbon spar package.

Standing rigging is Dyform stainless steel wire; rod rigging or composite rigging are available as options. The vang is a Boomkicker type. At the foretriangle, both traditional jibs and furling jibs can be used. Gennaker and Code 0 are masthead-set and flown from a retractable rectangular-section carbon bowsprit, housed flush in the deck.

All chainplates, as well as stanchions and bow and stern pulpits, are in stainless steel.

Construction

Hull and deck are built in sandwich construction, using unidirectional and biaxial glass fabrics over PVC and PET cores, vacuum-bagged in female molds and laminated with vinylester resin.

Internal hull structures are made of glass composite, CNC-cut, bonded, and subsequently laminated to the hull. Marine plywood bulkheads, also CNC-cut, are bonded and tabbed to hull and deck; the forward bulkhead is of collision-bulkhead type. All through-hull fittings are flush-mounted.

Keel

The keel, with a total weight of 1,350 kg, consists of a high-strength steel fin and a lead bulb, fully enclosed within a fiberglass fairing laminated in a female mold.

A cassette-type system allows quick installation and removal of the fin from the hull, facilitating transport on a trailer.

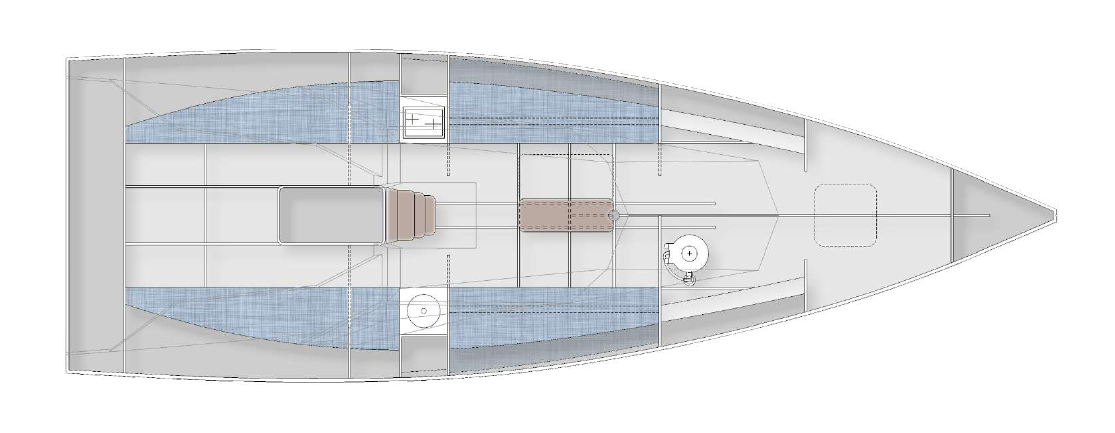

Lightweight and functional interiors, suitable for offshore racing

The interior reflects the same design philosophy adopted on deck: simplicity, robustness, and practicality. Crew rest is ensured by two structural low aft berths and two fixed upper berths amidships.

A longitudinal seat is located above the keel, opposite the navigation area, where a chartplotter can be installed; with an optional module, the seat can be converted into a folding-leaf table. Aft, two additional rigid seats are provided, separated from the central area by two furniture modules housing the galley and refrigerator.

The forepeak is left open and fitted with a sail-stowage hatch, while the WC area can be enclosed by an optional movable bulkhead.

The CG30 Vento is equipped for multi-day offshore use, featuring a refrigerator, sink, and a gimballed Jetboil stove. Two 55-liter flexible tanks are provided for fresh water and black water. The 12-V electrical system includes two separate batteries for engine and services, a control panel, 12-V outlets, four USB sockets, and interior cabin lighting.

Propulsion

Auxiliary propulsion is provided by an 11 Hp diesel engine with saildrive, cockpit engine controls, and a two-blade folding propeller. Fuel tank capacity is 40 liters.

Construction and marketing

The yacht is built by Northern Light Composites in Monfalcone. Sales will be managed directly by the shipyard in cooperation with selected specialized dealers.

Delivery of the first unit is scheduled for Autumn 2026.

Copyright © Cossutti – Ganz Yacht Design – Tutti i diritti riservati.

Technical specification

| Design & Naval Architecture: | Cossutti – Ganz Yacht Design |

| Systems: | IT Works Engineering |

| Builder: | Northern Light Composites |

| CE Category : | A |

| Hull Length: | 9,01 m |

| Max Beam: | 3,0 m |

| Displacement: | 2.950 Kg |

| Ballast: | 1.350 Kg |

| Draft: | 1,96 m |

| Engine: | 11 Hp / 8 Kw |

| Upwind Sail Area: | 56,6 mq |

| Downwind Sail Area: | 131 mq |

PRESS & REVIEWS

- Yacht.de – 20 Feb2026 – “CG30 Vento: Neuer Offshore-Racer für Zweihand und volle Crew von Cossutti-Ganz”

- Pressmare – 12 Jan 2026 “CG30 Vento: il nuovo 30 piedi offshore racer firmato Cossutti-Ganz e Northern Light Composites”

- Giornale della Vela – 10 Jan 2026 “CG30 Vento: il 9 metri che costa poco ed è tutto italiano”

- SoloVela.net – 9 Jan 2026 “CG30 Vento: il nuovo racer compatto di Cossutti-Ganz per regate accessibili”